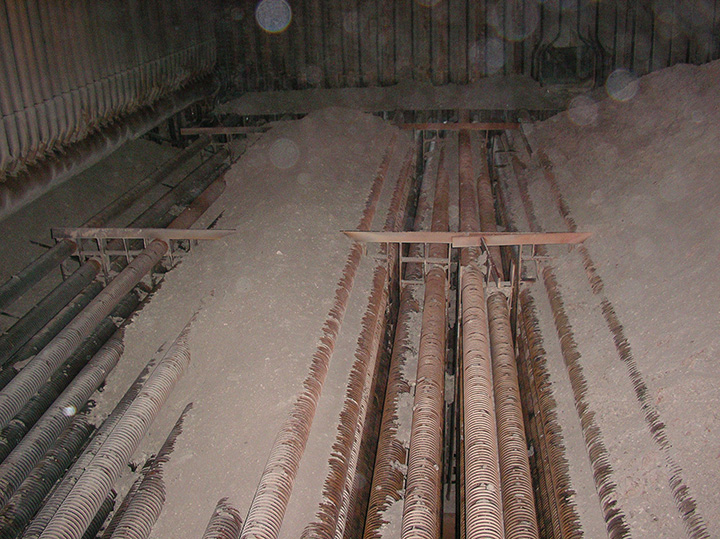

Sometimes, ash plugging of part of a horizontal bank can lead to higher flows in adjacent open regions. This can increase the likelihood of BTF’s in areas not typically susceptible to erosion.

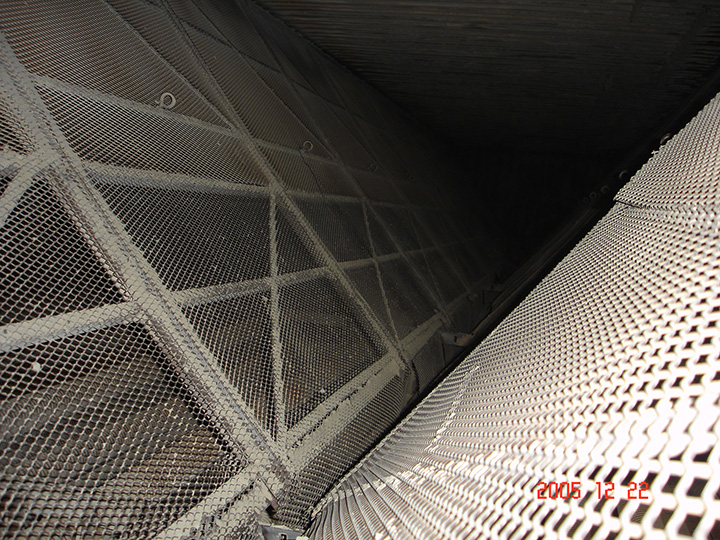

Controls, typically expanded metal screen, can be installed to prevent ash from plugging these sections by holding up the material until it is reduced to a size that would fall through the banks, or by deflecting it to areas where it could drain through to the hoppers. The trick is to install the controls to address the plugging problem without adversely affecting the gas flow or causing more plugging.

There are several successful applications of this concept in operating units. Aside from the benefits related to erosion reduction, added benefits include reduction in costs associated with cleanup, less damage to tube supports, and maintenance of normal heat transfer and gas side pressure drops.

If you have an ash plugging issue and would like to start a discussion, go to Power Gen Services for contact information.